Digitalization and automation characterize modern smart factories. As a pioneer, Leadec is breaking new ground here, developing and realizing appropriate solutions to make manufacturing fit for Industry 4.0.

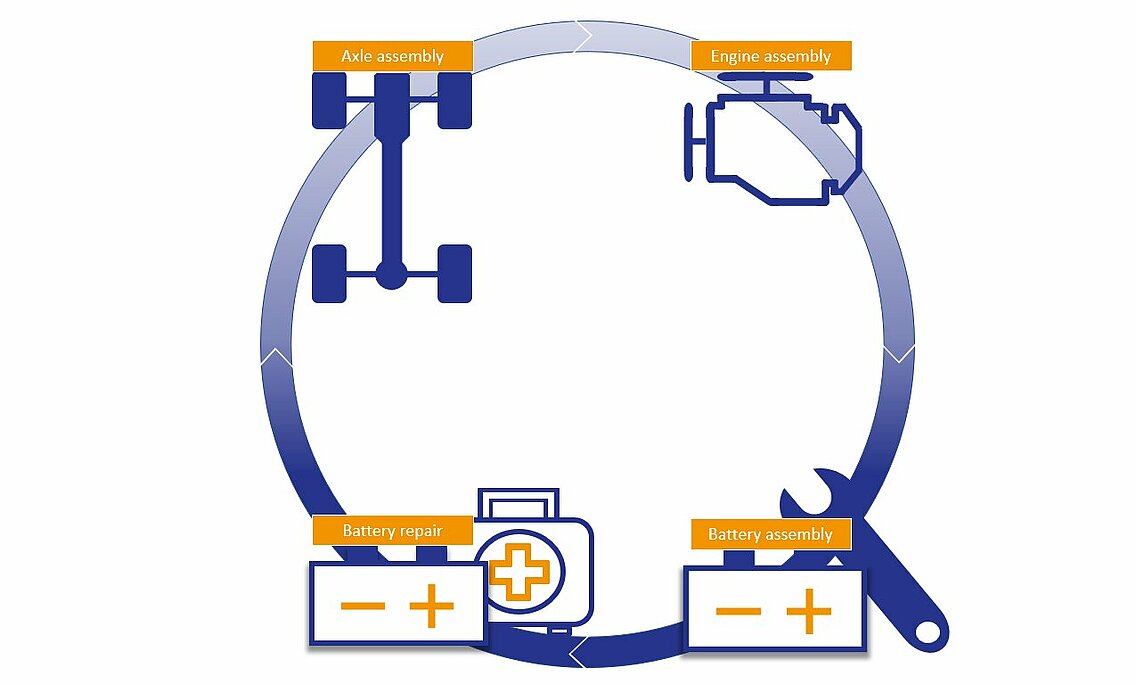

jitCATS - production control

Developed as a flexible system, jitCATS (just-in-time Control And Tracking System) has attractive features that reduce investment, commissioning time, changeover effort and running costs. Any OEM or module supplier can use jitCATS as a manufacturing execution system (MES) for the entire process. It includes the continuous control of all operating equipment, quality control loops up to shipping with sequence control.