References

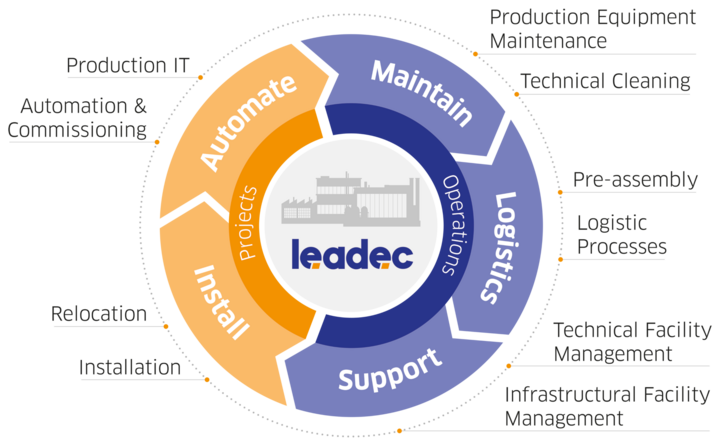

As a service champion, we are passionate about our customers. Our goal is to create a leading edge for them. A unique combination of customized services and highly qualified teams makes us the preferred partner of the manufacturing industries all over the world. With the following references, you can get a small overview of our wide range of services.