Around 1.3 billion people live in India, they move around in about 150 million vehicles. In 2020, just under 4,000 cars were sold that are purely electric. The market share is therefore less than 0.5 percent. Electric vehicles are also still more expensive in India than comparable ones with combustion engines. However, in view of rising fuel prices and necessary measures for more climate protection, electric vehicles are becoming increasingly interesting. The crux of the matter is that the cost of battery systems accounts for the largest share of vehicle manufacturing costs. So if these costs can be reduced – for example through more efficient production and greater automation of the manufacturing processes – acceptance and thus sales will increase.

Tricycle instead of car

However, because smaller, less powerful batteries with a lower output in kWh are cheaper overall, e-scooters and e-rickshaws are already spreading across India. They will continue to lead the way toward environmentally friendly transportation. And with new process technologies, manufacturing costs for more powerful batteries will also drop in the next few years, further opening the market for major OEMs like Tata. The forecast is that by 2030, as many as 5% of cars will be electric. To this end, Indian automakers will adapt their production processes accordingly in the coming years.

Outsourcing and partnerships

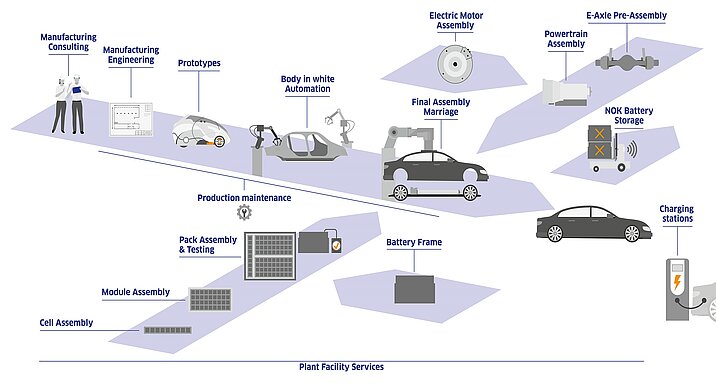

“In EV factories, pre-assembly or partial assembly, maintenance, audits, logistics and packaging or the automation of plant systems are particularly suitable for outsourcing,” says Sudhir Gurtoo, Managing Director of Leadec in India. Leadec’s advantage as a partner clearly lies in its experience in the field of e-mobility. Be it through projects to do with cell production and battery assembly, delivery logistics, planning and implementation of special fire protection and emergency concepts as well as quality assurance. Sudhir Gurtoo: “We offer an integrated concept from engineering to manufacturing support to maintenance services, combined with in-plant logistics and battery repair services. In this way, we give key players in the EV industry the opportunity to focus on market introduction and rapid production ramp-up.”

How the Indian market is developing

In addition to the 30% of vehicles expected to be electrically powered in 2030 - the aforementioned e-rickshaws and e-scooters will make up the bulk even then - the industry will be primarily challenged by changing production demands. It starts with the planning and ramp-up of new plants, through the redesign of existing plants, to the supply chain for the supply of batteries. This is where specialized experts are needed to provide technical services around the modern factory. And even though the development of the e-mobility market is promising, one point should not be overlooked: The relocation of production capacities for the manufacture of combustion engines to India will continue to play an important role in the coming years.

Video: Factory Talks about "E-Mobility"

Alternative drives and, above all, electromobility are the automotive industry’s innovation drivers. Battery production is one of the biggest challenges in this regard. What solutions are there? Find out in episode 1 of our Factory Talks.

You might also be interested in:

Interview in Pulse - The Golden Age of Industrial Services?

Whitepaper - Technical Services for Battery Production