Our Green Factory Solutions help you to prepare for Green Deal regulations – tailored to your business needs.

As part of the Green Deal regulations, many customers now require data from their suppliers as evidence of their supply chain sustainability. We understand the challenges you face with these new Green Deal regulations. At Leadec, we have services specifically tailored to the needs and challenges of small and medium-sized enterprises.

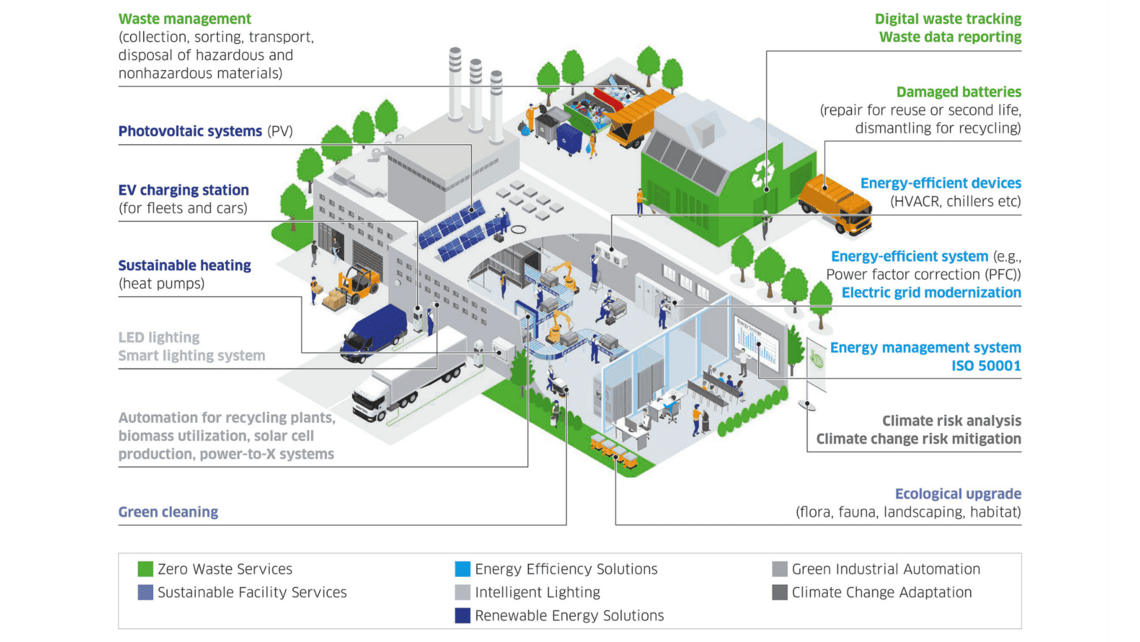

Start with our quick wins! By installing energy-efficient devices such as LEDs and optimizing HVACR, you can achieve significant energy savings. We can help you implement techniques like voltage regulation and load management to balance power consumption and boost overall efficiency. For long-term improvements, implementing an energy management system (ISO 50001) will improve your overall energy usage. Further by installing EV charging stations and sustainable heating solutions, you can get one step closer to decarbonization. Beyond energy savings, you can generate your own energy with our photovoltaic systems (PV). Our contracting model provides you with budget-friendly and smooth system installation. In addition to the decarbonization solutions, we offer Zero Waste Services to support you in your circular economy journey. We provide industrial waste management with the aim of reducing, reusing, and recycling waste.

With over 7,000 technicians and engineers, Leadec ensures factory transformation without production downtime.