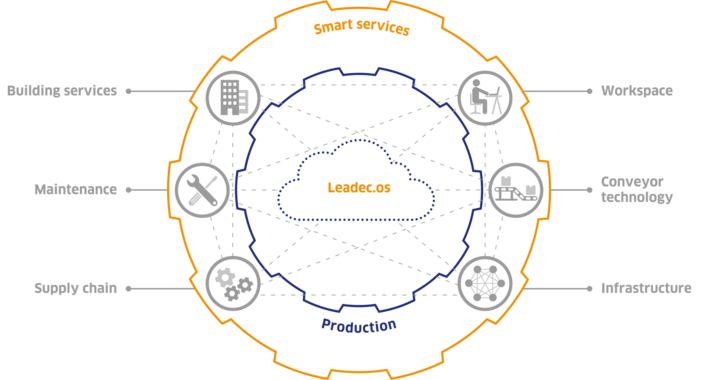

Our focus is generating value through business models in existing or newly developing digital ecosystems. We support our customers to bring factories to the next level of performance by transforming data to valuable insights and information. A broad technology portfolio and industrial IoT platforms are our enablers on the journey to the factory of the future.

Our core competences

IoT-based value creation

Our experts evaluate and create added value through the use of Internet of Things (IoT) technologies. Our many years of experience from numerous successfully completed projects form the basis of our expertise. We use our Leadec IoT Home Cloud, which is embedded in the Leadec.os platform. This allows us to connect and scale our IoT-based services. "Everything-as-a-Service" is our credo.

Partnering with industry platforms

We are partners of industry platforms, part of networked ecosystems and co-operate with academic communities to develop innovative solutions. In this way, we ensure that our customers benefit from a wide range of services.

Open innovation

A start-up mentality and the idea of open innovation are part of our DNA. We work with no boundaries and act as an interface with machine and software providers to create synergies. We are continuously engaged in research and development to drive forward future-proof technologies and solutions.

Digitization experts

Our team consists of experts in the field of digitalization of manufacturing processes and Industry 4.0. We generate valuable information by combining and processing data from various sources and systems in the factory. Leadec's factory experts support us in a seamless flow of information: from data collection and the development of APIs to structuring and enriching the data and visualizing the information. The result is automated data-driven activities on our own or on partner platforms.

Customer-centered approach

We focus on the individual needs of our customers and rely on long-term partnerships. We develop customized solutions for specific requirements. The Smart Factory Group is operating globally.

Production IT in-house developments

jitCATS

With our flexible system jitCATS - short for Just-In-Time Control-and-Tracking-System - investments, commissioning times, changeover expenses and running costs can be reduced. jitCATS can be used as a manufacturing execution system (MES) for the entire process. It includes the continuous control of all operating equipment, quality control loops up to shipping with sequence control.

WelD.One

With our WelD.One system, inline quality data of weld seams can be acquired, recorded and evaluated. All quality-relevant welding process data are digitally recorded and documented in real time via a communication interface. The evaluation is carried out by means of individually defined parameters by an algorithm, and further information from other quality assurance systems can be linked. The monitoring results provide a direct and permanent feedback into the automation process of the plant.

Our solutions for a smart factory

IIoT Strategy Assessment

Operating and machine data offer a wide range of opportunities to generate additional knowledge and the resulting added value. The IoT strategy assessment as the first step on the path to Industry 4.0 enables you to optimize the digitalization of your production.

Vibration Analytics

Vibration Analytics is Leadec’s IIoT solution that enables you to continuously monitor the condition of your pumps, motors and other rotating equipment. Condition monitoring on a new level. The plug-and-play solution requires no in-depth IT expertise, making it easy to implement and scale.

Smart vibration monitoring

How helpful would it be to prevent the failure of a system by being able to predict possible failures before they have an impact? This is exactly what Leadec has implemented for a customer and the oil extraction system in the production halls.

Retrofit of ventilation systems

With Leadec, you not only retrofit your ventilation systems but also use intelligent condition monitoring for a sustainable energy and maintenance concept. The fan concept consists of a combination of digital lubricant monitoring and intelligent vibration monitoring, which indicates damage at an early stage.

What drives us

'Connectivity, industrial platforms and data security regulations are enabling smart production in smart ecosystem. At Leadec we already service the entire factory life cycle. We see ourselves as a 'facilitator of the ecosystem' and as such look deeply into integrated service concepts including flexible pay-per-X models.'

Dr. Bernd Voelpel, Global Head of Smart Factory Group