Elevate your parcel delivery solutions

Online retail and parcel delivery has experienced steady growth and continues to overcome the many challenges experienced in recent years. Changing customer behavior and expectations are presenting the industry with new challenges, such as increasing volumes, faster shipping and growing product diversity.

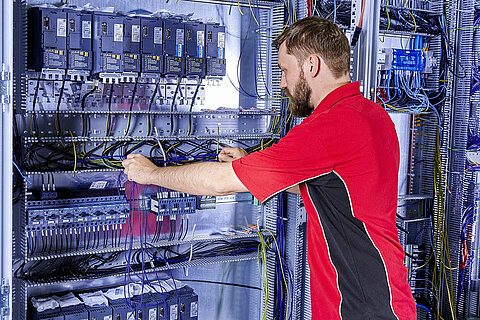

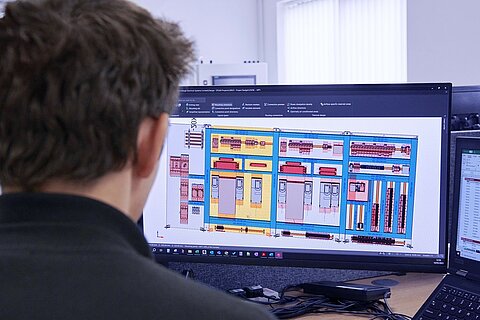

Automation and retrofit

Leadec supports you with automation and software solutions as well as innovative conveyor and sorting technology, helping you to optimize your processes, reduce downtime and increase operational performance. We are integration specialists for the planning, assembly, and installation of electrical and mechanical automation systems. We also upgrade and retrofit existing sorting systems to bring them up to date and increase their efficiency.

Along the entire lifecycle

As a leading service specialist, we continue to support you during ongoing operations, whether maintenance, facility management, technical cleaning, or logistics. We can draw on more than 60 years of experience in industrial services. Our Leadec.os business platform records all processes digitally from end to end and creates seamless interfaces to the customer’s systems. This creates maximum transparency in the planning and provision of all services.