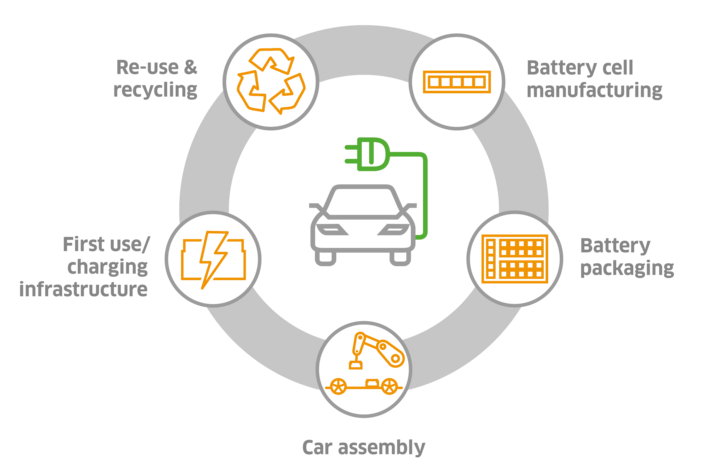

Solid-state batteries are the new stars in the battery sky: fire- and explosion-proof, 15-year lifespan and cheap to produce. In Saxony (Germany), the company Altech wants to manufacture the new batteries. Leadec is responsible for the planning of plants and production processes for the future-oriented manufacturing site. The Altech's Group future production plant is expected to produce 10,000 battery modules per year, each with a capacity of 10 kWh. There are many possible applications for the solid-state batteries.

The batteries will be used in stationary energy storage systems, for example for renewable energies (wind, solar), as a component of the charging infrastructure for e-vehicles and in industry. Batteries also serve as home energy storage systems to provide a buffer between power generation and power consumption. And last but not least, electricity suppliers can avoid peak load capping in their megaparks.

Learn more