Food and beverages are among the most important goods produced worldwide. Plant downtime - whether due to technical failures or a lack of skilled workers to maintain the machines - poses ever greater challenges for companies.

This is also the finding of a 2021 State of Industrial Maintenance Report survey, in which 36% of respondents experience problems when experienced employees leave the workforce, and 49% have difficulty recruiting skilled workers with technical skills at all. Overall, 80% of respondents said that machine downtime is affecting productivity in their operations.

Many companies in the sector are looking for a more strategic and fundamental solution to the current and future challenges.

This strategic solution can be summarized in two concepts:

- Crossing the yellow line’ – identifying a specialist facilities partner who has the right experience, knowledge and tools to deliver efficient and reliable maintenance to production assets and plant, and remove the traditional demarcation ‘yellow line’ between in-house and outsourced maintenance teams

- Integrated facility management - A wide range of services is bundled and outsourced to a specialized partner. This allows the company's own employees to concentrate on their core tasks.

How to successfully switch to an IFM model

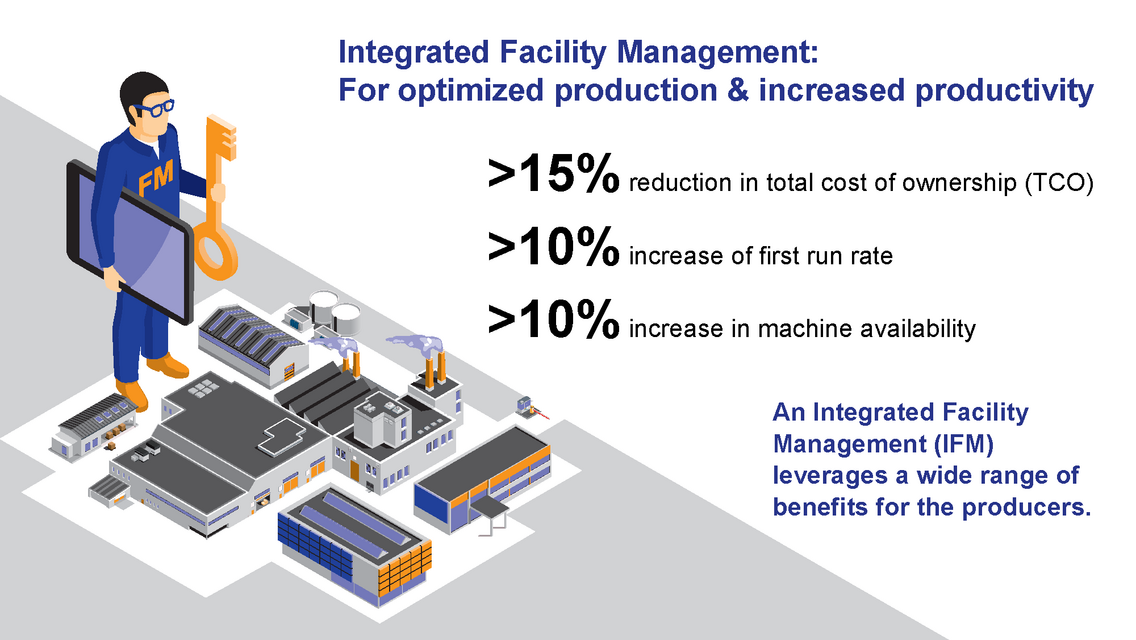

With Integrated Facility Management (IFM), the results and key figures of the services become more strategic. And supplier management must also be approached more as a partnership.

Under an IFM model you typically not only outsource the operational activity of the services, but also a portion of the tactical and the strategic alignment would become a joint responsibility for you and your future partner. Usually what we see as an IFM package is a consolidation of Hard (technical) and Soft (nontechnical) services. Hard services include asset/machine maintenance, mechanical & engineering equipment, HVAC, BMS, and building fabric maintenance & repair. Soft services include janitorial/cleaning, mail room, grounds maintenance, pest control, waste management, transport, office support services, and food.

Where is the trend going?

In the future we expect this to expand further into the production areas, as there is clearly much untapped potential on that side of the ‘yellow line’. For food and beverage producers to be able to simply concentrate on the core business, an attractive strategic solution is outsourcing support services through an Integrated Facility Management (IFM) model. With the right IFM partner this offers:

- Freedom from allocating your people resource to non-production activities

- Clear focus on production and sales

- A single interface with one primary provider, which profoundly simplifies procurement and client management of service providers

- The right IFM provider with technical knowledge and ready-made technology solutions provides a faster route to optimized assets and production levels

- A committed and accountable long-term partner aligned to your objectives of maximizing production output and the needs of the company’s assets

- A partner with a strong focus on providing an excellent workplace experience for your employees • Streamlining of all support services through a single efficient model

- Accessing innovation, technology and best practice across all support services

- Driving and achieving defined cost savings through a clear facilities budget and explicit contract focused on delivering outputs

Download

The whitepaper provides an overview of current challenges and opportunities in the food & beverage industry. In particular, under-utilization of plant and equipment and maintenance costs are having negative impacts. Learn more about how Integrated Facility Management (IFM) optimizes production by streamlining all support services through a single efficient model.