Where is which waste generated in production facilities and in what quantities? “Digital Waste Tracking” developed by Leadec provides an overview of this. Following the successful completion of a pilot project, the digital solution has been used throughout the waste management system at the plant in southern Germany since January 2024. It is currently being implemented at the plant in northern Germany and will go into regular operation in March.

“Our digital solution enables comprehensive tracking of disposed residual materials. As a result, our customer can not only reduce disposal costs, but also make production more sustainable overall,” explains Alexander Bonk, SVP Operations Leadec Germany.

IoT-optimized waste management

Not all waste is the same. It ranges from plastics, metals and spray cans to adhesives, industrial waste and paint sludge. To be able to dispose of each type of waste appropriately, Leadec provides all waste containers and their respective locations with QR codes. The team collects the containers directly from the factory building, weighs them and records their data using a mobile infrared scanner.

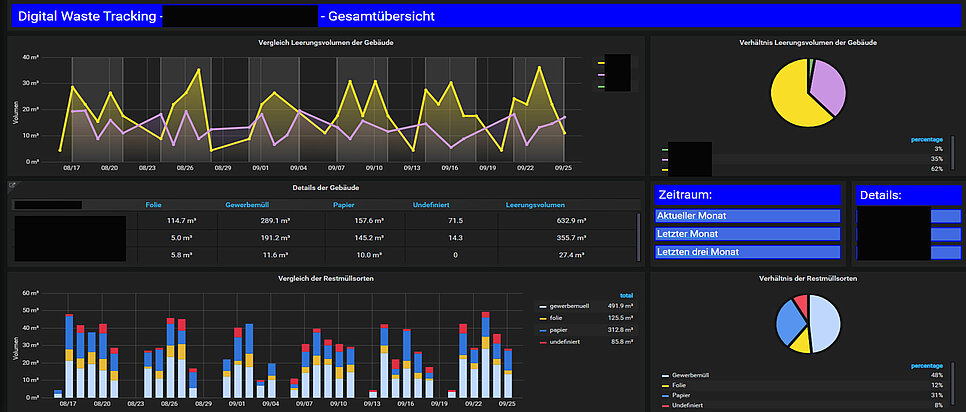

The data is then processed in real time on the Leadec IoT platform. The emptying of the containers is linked to the respective generators of waste. Based on this data, the service specialist can precisely record the emptying of the individual containers along with the respective types and quantities of waste and optimize the routes. The aim is to identify potential savings in waste along the value chain, increase the recycling rate and adapt waste management services.

Developed from practical experience

Leadec has been providing the car manufacturer with internal waste management services at the plant in southern Germany for ten years. The entire waste management process at this site is now being digitally mapped and optimized. Other material flows such as mixed scrap containers, waste oils and hazardous substances are recorded and also integrated into the system. The order for waste management at the plant in northern Germany is new.

The “Digital Waste Tracking” solution developed by Leadec helps to identify potential savings in waste along the value chain.