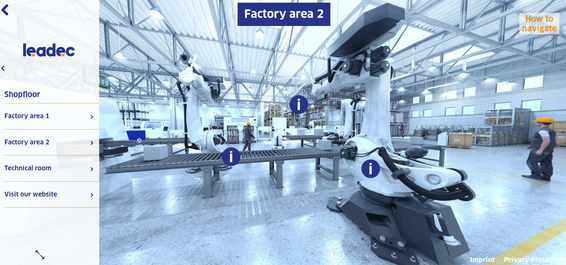

From autonomous transport systems to digital weld seam testing - Leadec's range of products and services for the smart factory can now be experienced in a simulated environment. This is now available with a tour on the online platform "Digital Factory Experience".

Two robot arms work precisely and at high speed at a common workstation. Their distinctive programming allows a high cycle rate while preventing collisions. Sensors on a cleaning robot act like dirt detectives and enable the cleaning device to be active at precisely the point in the factory where the need is particularly great at the moment. The machine independently calculates how much water and cleaning fluid to use. And while production is running, the power supply system regulates the use of cooling and lighting. All this works at the same time when machines, equipment and systems in a smart factory communicate with each other and organize themselves. And all around, there are services in the smart factory that create added value. They, too, must be digitized and smart.

Online platform provides insight

Leadec is the service specialist for the factory of today and tomorrow. In the "Digital Factory Experience" visitors move intuitively through a modern factory landscape. Here they can experience where digitized services can be found, how the performance of plants and the quality of services can be checked, how robots work together or how the right time for maintenance is determined for an assembly line.

You might also be interested in:

Video - Leadec's services in the field of e-mobility

Article in Leadec Pulse - IoT-Orchestrated Services: Basis for Machine Learning and Co.