“It's Often About a Higher Level of Automation”

Mr. Leitner, you have been working on acquiring new customers in the parcel and warehousing sector and expanding our services since 2022. Why is this market so important to Leadec?

This market segment has grown disproportionately in the last five years. This has to do with our buying behavior and the coronavirus pandemic. The volume of e-commerce alone has doubled in the last three years.

To meet the growing demand, companies have built or commissioned many new centers. Only a few companies such as Amazon deliver themselves. As a result, parcel delivery companies have also expanded their networks accordingly.

In the past, we have already worked in the logistics centers of automotive manufacturers, for example in the area of spare parts management. We can transfer these services to parcel and e-commerce logistics centers.

With Diversified Automation in the USA and Elmleigh in England, Leadec already carries out many projects in this area.

Diversified Automation in the USA has been part of the Leadec Group since 2020, and Elmleigh in the UK was added in 2022. Both have been involved in projects in this market segment for many years.

DA focuses on customers from the parcel distribution center or the e-commerce sector in the United States. The company provides its system controls and software solutions to leading manufacturers of warehouse and conveyor technology, who in turn work for global parcel service providers and online retailers.

Elmleigh is a process automation specialist and systems integrator. Its customers include some of the largest companies in the parcel distribution center sector in the UK and Europe. They are also represented with their services in the food and beverage segment, which also promises good margins. Services range from planning and project management to electrical and mechanical installations, control cabinet fabrication, ATEX installations and software and automation solutions.

How do parcel and logistics centers differ from other factories?

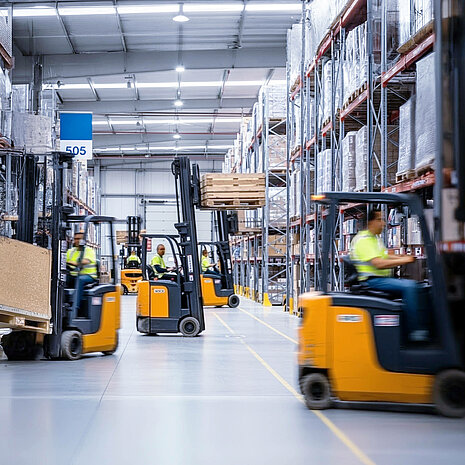

The biggest difference is that nothing is usually manufactured here. In parcel centers, parcels are collected, sorted several times according to destination, and delivered. In logistics or e-commerce centers, products are stored and retrieved on order and shipped by the parcel delivery company. Some of this is highly automated.

Again, all systems require regular maintenance, plus mechanical and electrical installations, retrofitting of sorting systems, PLC programming and facility management services - all disciplines we are familiar with.

Depending on the size of the sorting centers or warehouses, we can support our customers with either on-site teams or field service teams.

Where do you see the greatest opportunities for us in this area in the future?

We see the greatest demand for projects and maintenance services. The focus here is on modifications, retrofits and optimizations in existing centers. The goal here is often to achieve a higher level of automation, for which we also work together internationally, e.g. DA's experts provide support with their knowledge in Brazil.

On the other hand, local maintenance is also required. In the past, maintenance was often carried out by the integrators (plant installers), who had the contract as general contractor - with corresponding prices. Our advantage as a technical service provider: we are manufacturer-neutral, flexible and close the gap between integrators and traditional facility management providers.