"Our Strength is Our Responsiveness"

Mr. Haas, why has Leadec established a new company for the French market?

Ulrich Haas: For historical reasons, Leadec has been operating in Eastern Europe for a long time. In Western Europe, we have not been present until now with the exception of the UK.

France is the sixth largest economic power in the world and the second largest in the European Union. It was therefore obvious to us that Leadec should establish a subsidiary in France.

Unlike Germany, France has a very diversified economy. Leadec has a strong footprint in the automotive industry, and we also want to become stronger in the aviation, food and pharmaceutical industries in France.

How do you intend to strengthen the competitiveness of French companies?

Leadec has a very strong technical focus. We have specialized experts here on site and also exchange ideas with teams that come to France from Germany on a selective basis.

We don’t say for nothing that we are at home in the factories. Accordingly, we know the challenges very well and are therefore very fast when it comes to implementation – regardless of the location or the type of service. Our customers in France will benefit from our global expertise, which we will also apply there.

Our strength is our responsiveness: We don’t have to reinvent things, as we can draw on our expertise as well as experience gained from working for large corporations, particularly in the automotive sector. A recent example is a manufacturing company based in western France, which we support in terms of CSR and digitization.

How do you support your customers, especially from the automotive industry, with regard to electric vehicles?

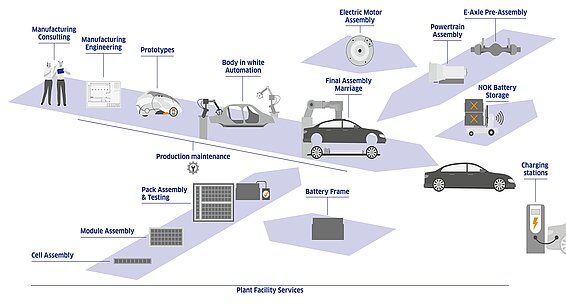

Electric vehicles are a great opportunity for Leadec because the automotive factories around the world are where we work. We have been involved in the design or automation of many of the manufacturers’ major factories and take care of maintenance services for years.

We bring our expertise to the assembly of an internal combustion engine as well as to that of an electric motor, battery modules or batteries. In France, we already have some maintenance projects for battery production plants.

Leadec offers green solutions, the “Green Factory Solutions.” How important are they in France?

The Paris Agreement for Climate Protection (COP21) calls for a reduction in greenhouse gas emissions and this is also a high priority in French society. Companies in France are therefore looking for ways and solutions to reduce energy consumption in the long term. The French government is also aiding the industry. We ourselves notice among our customers that they are actively working to reduce their energy costs, for example. We naturally see great potential here to contribute our services.

For example?

Leadec plans, installs and maintains photovoltaic systems, for example on factory roofs. This enables companies to generate part of the electricity they need for production processes and the factory building themselves. To ensure that this works optimally, we also modernize the factory’s own power grid into which the solar energy is fed and install battery storage systems on site.

We are also converting large areas in factories to LED lighting. The combination of daylight sensor, motion sensor and the LEDs can reduce electricity consumption for lighting by at least 70%.

Another example is control and automation solutions such as those used in recycling plants. Here, it is important to use software to control the complex and energy-intensive processes – such as shredding, sorting and drying – in such a way that as little energy as possible is consumed. To do this, the equipment in the plant records the power consumption of the main consumers, measure the volume throughput and use the software in the background to ensure that energy is supplied in an appropriate way.

Where is Leadec headed in France?

Leadec France is headquartered in Nanterre, but we will gradually establish ourselves in other French regions, particularly in Angers in the west and the Hauts-de-France and Grand Est regions. In this way, we create proximity to our (potential) customers. At the same time, we want to be perceived as an attractive employer. Because the challenge for us, too, is to find skilled workers.

And as far as our range of services is concerned, in addition to sustainable services, we also want to roll out our Leadec.os platform further to digitize all service processes end-to-end.