On October 1, 2023, there were a total of around 108,300 public EV charging points across Germany. With over 22,400 charging points, most of them were in Bavaria. The ambitious goal of the EU and the German government is to have one million charging stations by 2030. In other words: a charging point every 60 kilometers.

Infrastructure from A to Z

Investments in charging infrastructure are enabling new business models. Major car manufacturers, among others, are entering the stage and opening their own charging parks. To this end, Leadec teams are providing their Renewable Energy Solutions in northern Germany. “The demand for charging infrastructure is enormous,” says Holger Beschenboßel, who heads the design department at Leadec in Hanover. “This involves all aspects: the installation and commissioning of charging points, as well as their monitoring and maintenance, are crucial to the success of charging and thus the ‘e-mobility boom.’”

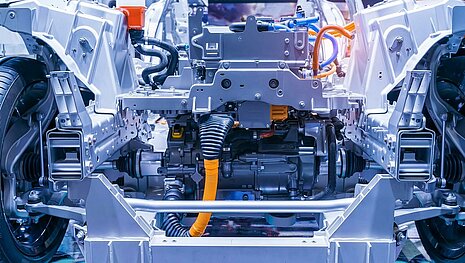

Technical expertise for optimum voltage

Leadec has been involved right from the start and is supporting a major operator of charging stations with their pre-assembly and final assembly. “This gives us a precise insight into how the stations are constructed – which makes it easier to maintain the systems later on,” says Holger Beschenboßel. But it doesn’t stop at assembly: the Leadec teams also take care of the ground installation of the charging points, including laying the cables, and connect them to the existing power grid. Beschenboßel, head of the design department, points out: “Once everything is in place, we commission the systems, check the control panel and communication system and hand over the system to the operator after legally compliant acceptance.” In this way, Leadec has installed around 23 charging stations in northern Germany in recent years – and the trend is still rising.

A watchful eye at all times

Nothing can make drivers of electric cars break out in a sweat more than reaching a charging station that is not working. To avoid this, Leadec also takes on the monitoring, maintenance, and servicing of charging stations. “We continuously check the values of the devices. In the event of a fault, we receive an alert immediately and can either rectify the fault via remote maintenance or set off to repair defective systems,” says Beschenboßel, describing the process. To prevent this from happening in the first place, Leadec is also responsible for the regular inspection and preventive maintenance of around 530 charging stations at present. Here, too, the number is constantly increasing.

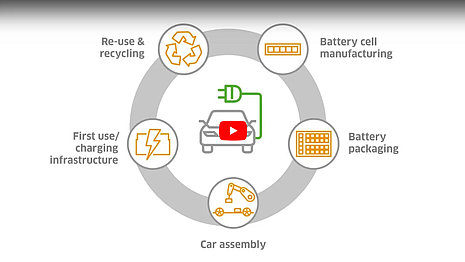

About Leadec’s Green Factory Solutions

Leadec’s Green Factory Solutions have two central thrusts in the factory: decarbonization and circular economy. The services include zero waste, automation, lighting, climate change, sustainable facility management, energy efficiency and renewable energy solutions. Leadec has set up “Green Hubs” at a total of seven locations in Germany – including Hanover – and one location in England to bundle its activities and is gradually expanding them.